Cable Tray Plastic Sheet

FREE SHIPPING

Our Cable Tray Plastic Sheet is designed to provide a solid surface for the bottom of cable trays. This helps to prevent the snagging of cables and wiring. The high density polyethylene plastic (HDPE) provides a smooth surface which allows for the easy passing of cabling and is flexible, allowing the plastic to conform to various tray features. The material is easily cut with a utility knife which makes customizing the liner to various cutouts and openings simple and straight forward.

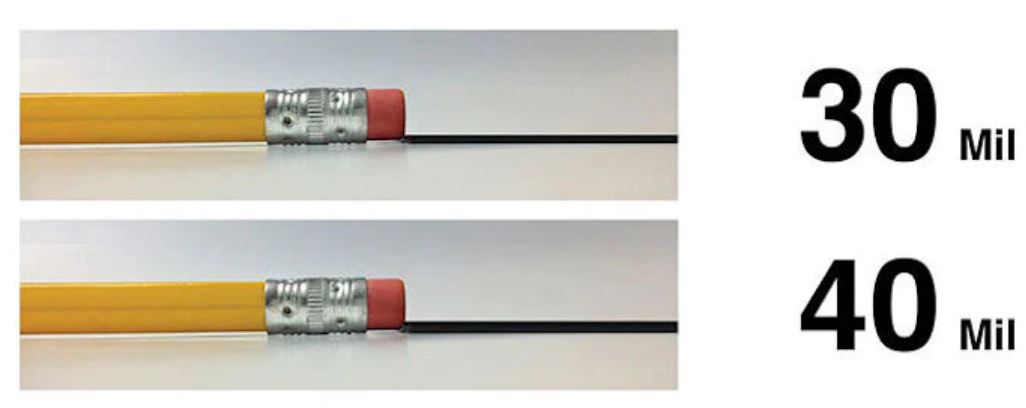

Available in both 30 mil and 40 mil thicknesses, our cable tray liner is available in a wide variety of roll widths ranging from 18” - 48” and in 100’ roll lengths. Our liner is made in the USA and ships from Kansas City.